Electroplating

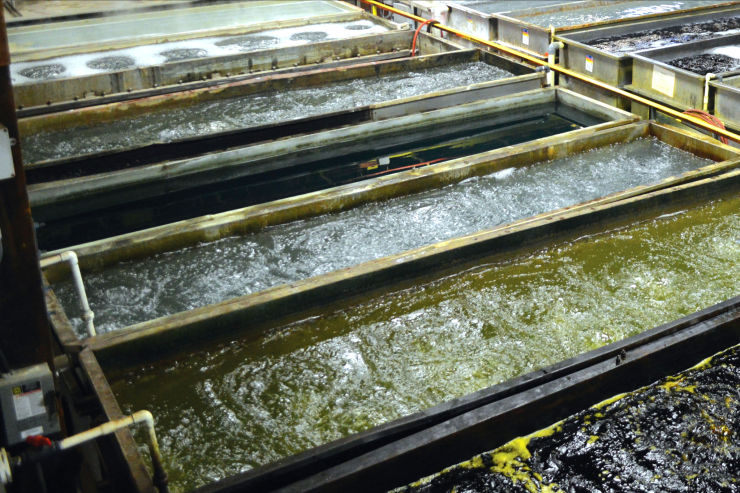

Electroplating is a metal plating technique used to coat an object with a layer of metal, typically gold, silver, nickel or copper. The process involves immersing the object, also known as a workpiece, in a bath of electrolyte solution containing metal ions. By applying an electric current, the ions are deposited on the surface of the workpiece, creating the desired metallic coating.

Alkaline and acid copper

Alkaline copper is a softer, more uniform copper bath, used for plating delicate objects. Acid copper is stronger and is used to coat more resistant objects.

Boric Acid

It is used as part of some metal surface finishing formulations. Its most common uses are in the manufacture of fiberglass monofilament and for the production of induction furnace linings and ceramic materials.

Brass Anodes

70/30 brass is soft at room temperature; they can be easily molded. It contains 30% zinc and 70% copper. It can be rolled, soldered, bent and drawn without temperature increase. It is widely used for decorative applications in antiques and oxidized finishes.

Brighteners

These are products that clean, restore and brighten all types of metal surfaces. They are used after galvanizing to improve brightness and color, prevent stains and protect against wear, corrosion and impact damage.

Caustic soda flakes

It is used in cotton textile processing, laundry and bleaching, oxide coating, electroplating, electrolytic extraction, soap making, paper, dyeing and petroleum products.

Chromic acid flakes

It is used for wood preservation, metal chrome plating, in the manufacture of catalytic converters, in the production of magnetic tapes for engraving and in anodized aluminum, it gives the metal resistance to corrosion.

Copper sulfate

It is the salt of sulfuric acid and copper, formed in the second degree of oxidation. In electroplating industry, it is used as ionic additive for copper sulfate plating and full bright acid copper plating at wide temperature.

Degreasers

They are used to remove residues of grease, metal oxides, cutting oils, lubricants or other products that need to be cleaned from metal surfaces. Sometimes parts arrive with a layer of anti-corrosion and anti-rust oil that needs to be removed.

Electrolytic nickel

It provides protection against corrosion and wear resistance, it represents the deposition of the nickel layer by the action of the electric current on the parts to be coated that are in contact with the electrolytic solution.

Lead Anodes

It is used as a component in electrowinning cells. Anodes conduct high electric current densities. They are used in electrolysis processes (galvanizing and chromium plating). They are highly resistant to seawater corrosion.

Nickel chloride

It is used to manufacture catalysts. In the electroplating process, an electric current is used to coat a conductive material to provide: hardness, increased corrosion resistance, wear resistance, increased ductility.

Nickel sulfate

It is used in electrolytic baths, as electroplating, in synthesis, organic, metallic colorant, mordant for dyes, in the manufacture of nickel salts and Ni-Cd batteries.

Passivators

They remove foreign reactive ions from the metal surface that inhibit the formation of protective oxide films. The removal of these ions renders the surface inert and promotes the development of an oxide film when the surface is exposed to the atmosphere.

Tin Anodes

Tin anodes are used in electroplating to coat objects with a layer of tin, which protects the object from corrosion and improves its appearance and electrical properties. They are also used in batteries and electronic devices.

Tin Sulfate

It is used to coat objects with a layer of tin. It is also used in the production of glass, ceramics and pigments. It is also used in the manufacture of surface finishes, protective coating of copper, iron and other metals.

Zinc Anodes

Zinc anodes are used to protect objects from corrosion. In galvanizing, the object is coated with a layer of zinc to prevent rusting. They are also used in boats and ships to protect metal parts from corrosion caused by salt water.

PROVIDING INNOVATIONS

Quote now

We focus on building long-term sustainable businesses.